The Future of Style: Exploring DTF Printing Technology in the Fabric Industry

In the last few years, the textile market has experienced a marked change in the direction of innovative modern technologies that are reshaping the landscape of style production. Amongst these developments, Direct to Film (DTF) printing modern technology has emerged as an appealing contender, supplying distinct capacities and chances for developers and producers alike. This cutting-edge printing technique has actually stimulated rate of interest due to its prospective to revolutionize typical textile printing processes. As we delve right into the effects and opportunities of DTF technology in the world of fashion, it becomes evident that its integration might redefine sector criteria and lead the way for a new age of imaginative expression and efficiency.

Evolution of Fabric Printing

From the old human beings making use of methods like block printing to the digital revolution of today, fabric printing has actually continuously pushed boundaries. As the craft spread to various other parts of the world, brand-new techniques such as screen printing and roller printing emerged throughout the Industrial Transformation, transforming the fabric market.

The intro of electronic fabric printing in the late 20th century noted a considerable change towards even more functional and sustainable printing approaches. The evolution of textile printing showcases an abundant history of imagination, resourcefulness, and technological progression in the world of style and design.

Advantages of DTF Technology

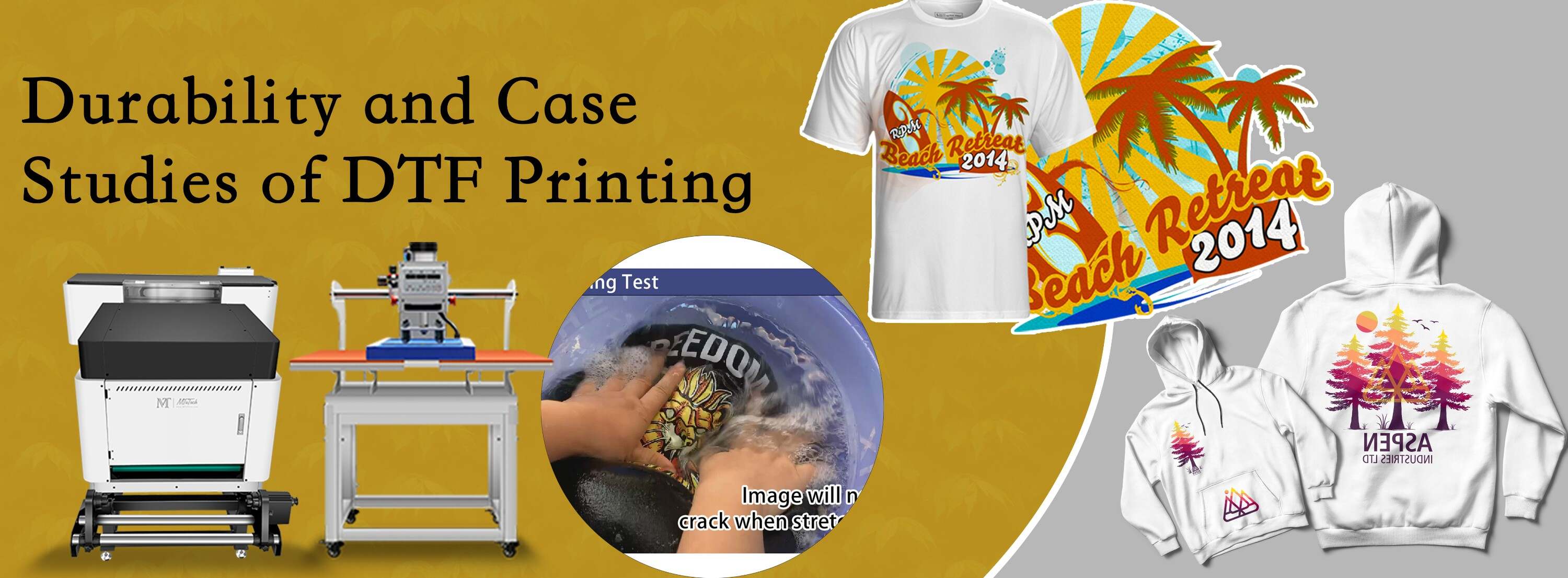

With the development of fabric printing techniques from ancient approaches like block printing to contemporary advancements such as electronic printing, the intro of Direct-to-Fabric (DTF) modern technology has actually considerably enhanced the efficiency and sustainability of fabric printing procedures. Among the primary advantages of DTF technology is its capability to directly print styles onto material without the demand for transfer documents, which lowers waste and simplifies the manufacturing procedure. In addition, DTF printing enables better shade vibrancy and detail precision compared to conventional techniques, allowing textile producers to produce high-grade and detailed layouts easily.

Moreover, DTF modern technology is understood for its convenience, as it can be made use of on different sorts of materials, including all-natural fibers like woollen, silk, and cotton, in addition to synthetic materials such as polyester and nylon (DTF Printing). This flexibility opens a large range of possibilities for makers and designers to experiment with various appearances and products, resulting in more cutting-edge and special items in the apparel industry. Overall, the execution of DTF innovation represents a substantial innovation in textile printing, offering many advantages that add to the future sustainability and creative thinking of the market

Sustainability in Fashion Manufacturing

Highlighting green methods is paramount in modern fashion manufacturing, lining up with the growing consumer need for additional resources lasting products. Over the last few years, the style market has encountered raising examination due to its substantial environmental influence, including too much water usage, chemical air pollution, and textile waste. As an action, many fashion brand names are currently incorporating lasting practices right into their production procedures to reduce injury to the atmosphere.

Sustainability in style production includes numerous elements, such as making use of recycled and natural products, decreasing power intake, executing honest labor practices, and promoting openness throughout the supply chain. Additionally, improvements in modern technology, like DTF printing, offer chances to better enhance sustainability in textile production. This technology allows precise printing on textiles, decreasing ink wastage and water usage contrasted to typical printing methods.

Design Freedom and Personalization

Furthermore, DTF printing promotes personalization on a range previously unattainable, enabling for individualized clothes and one-of-a-kind pieces customized to individual preferences. On the whole, DTF printing technology reinvents the layout landscape in the textile market, supplying unlimited opportunities for creative expression and individualized style.

Effect On Supply Chain & Market Trends

DTF printing modern technology in the fabric market is reshaping supply chain dynamics and affecting market fads with its Our site effectiveness and personalization capabilities. By enabling on-demand printing and eliminating the demand for huge stocks, DTF technology streamlines the supply chain procedure.

In addition, the personalization capacity of DTF printing technology is revolutionizing the marketplace patterns in the textile sector. Customers increasingly look for special and individualized items, and DTF allows brand names to use bespoke layouts cost-effectively. This modification ability not only boosts customer complete satisfaction yet likewise opens up brand-new opportunities for organizations to provide to niche markets and separate themselves from competitors. As an outcome, DTF technology is driving a change towards even more cutting-edge and customer-centric methods within the fabric industry, forming the future of fashion.

Verdict

Finally, DTF printing innovation is changing the textile market by supplying various advantages such as layout sustainability, flexibility, and modification. This ingenious modern technology is improving the future of fashion production, impacting supply chains, and driving market patterns in the direction of extra green and reliable techniques. As the industry continues to develop, DTF printing will play a vital duty fit the way textiles are produced and consumed in the years to come.

From the ancient worlds utilizing techniques like block printing to the digital revolution of today, fabric printing has actually consistently pressed borders. As the craft spread to various other components of the world, new methods such as screen printing and roller printing arised throughout the Industrial Transformation, reinventing the textile industry.

The introduction of electronic fabric printing in the late 20th century marked a considerable shift in the direction of even more versatile and sustainable printing approaches.With the advancement of textile printing techniques from old approaches like block printing to contemporary developments such as digital printing, the intro of Direct-to-Fabric (DTF) innovation has significantly boosted the effectiveness and sustainability of textile printing procedures (DTF Printing).In action to the critical change towards sustainability in style manufacturing, the adoption of cutting-edge innovations like DTF printing not only addresses ecological issues yet likewise opens up avenues for unparalleled style freedom and modification in the textile sector